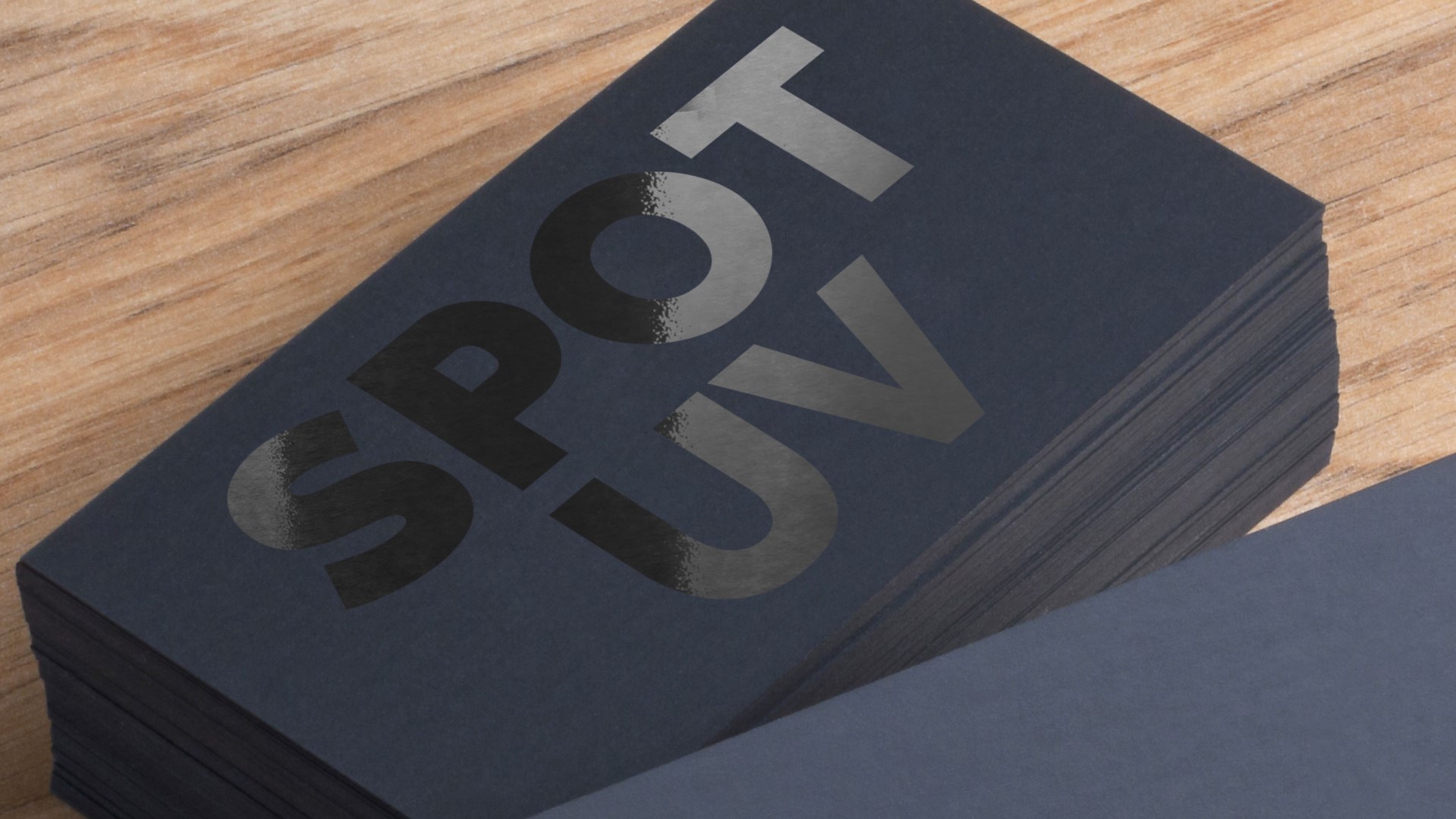

Spot UV at a Glance

Spot UV coating is a transparent varnish that is cured and hardened using ultraviolet light. It provides a premium look and feel to printed materials, creating a raised and glossy effect that enhances their visual appeal. The coating also offers durability and protection, making it an excellent choice for packaging and print materials. Spot UV coating is versatile and can be applied to various materials, making it a popular embellishment in the printing industry.

Spot UV is a popular printing technique that adds a glossy finish to specific areas of printed materials, creating visual interest and enhancing the overall look of the product. In this article, we will explore what spot UV is, how it works, its various uses, and the benefits it offers.

We will also discuss other digital embellishments that can be combined with spot UV for added impact.

What is Spot UV?

Spot UV is a type of finish or digital embellishment that utilizes polymer resin and ultraviolet light to create a glossy, protective layer on printed materials. Unlike general UV coating, which covers the entire surface, spot UV is more targeted and is applied only to specific spots or areas, making them stand out.

The process of spot UV printing involves several steps. First, the client provides a mask file that indicates where the coating should be applied. The printer follows the lines and edges specified in the mask file to ensure precise application.

Next, a thin film is placed over the sheet, and UV varnish is spread across a die-cut template. The varnish is then cured and hardened by exposure to ultraviolet light, resulting in a raised and glossy effect on the designated spots. It is important to keep the use of spot UV minimal and focus on the message or artwork to avoid a cluttered design.

Uses of Spot UV

Spot UV coating has a wide range of applications across various industries. Here are some common uses:

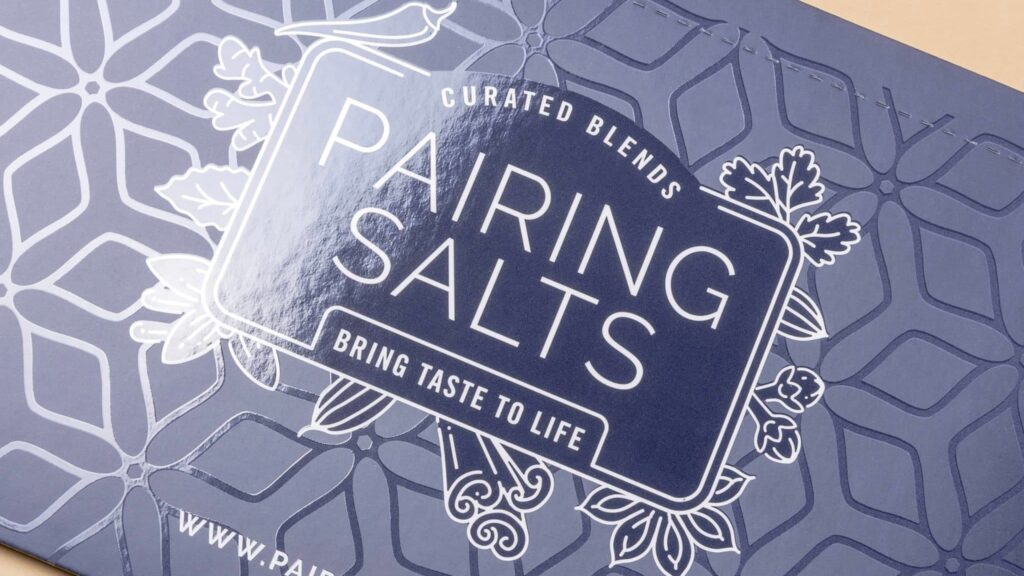

Packaging

Spot UV coatings are often used in packaging to add decorative effects and grab the attention of consumers. The coated portions of the packaging create a sense of sophistication and make the product visually appealing.

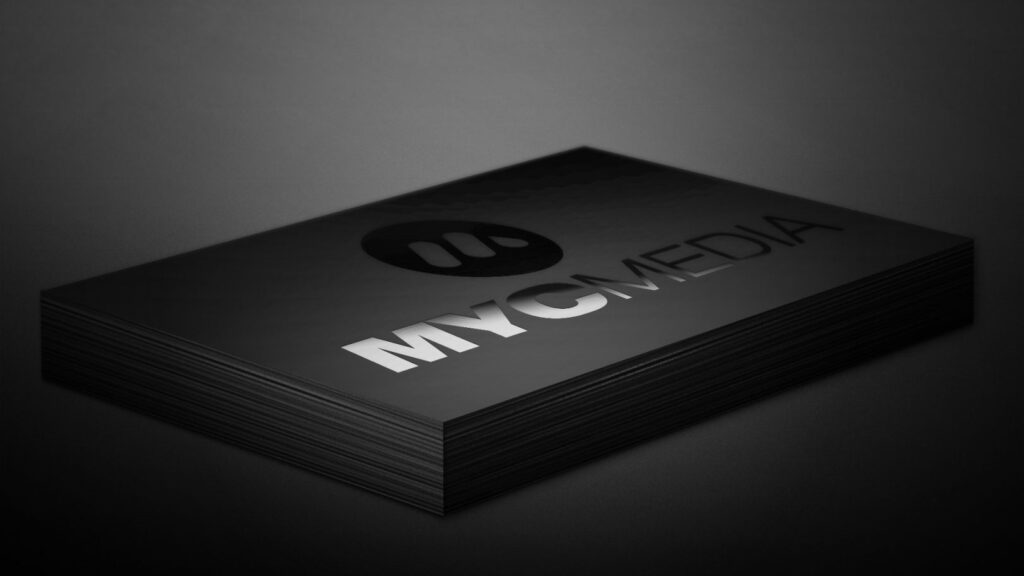

Business Cards

Spot UV coating can make business cards more memorable and visually striking. By adding this unique printing technique, you can leave a lasting impression on potential clients and professional connections.

Brochures and Flyers

Incorporating spot UV coating into brochures and flyers can make them more engaging and visually interesting. The added texture and shine create a tactile experience and enhance the overall appeal of the printed materials.

Postcards

Spot UV coating on postcards not only adds an extra level of visual appeal but also protects the message and design, even without an envelope. It adds a touch of thoughtfulness and makes the postcard more impactful.

Packaging Boxes

Spot UV can be applied to packaging boxes, not just the product itself, to create a cohesive and visually appealing presentation. It showcases attention to detail and enhances the overall consumer experience. Spot UV also adds durability to the packaging for transit.

Benefits of Spot UV

Spot UV coating offers several benefits that make it a popular choice for enhancing printed materials:

- Top-Notch Shine: Spot UV produces a high-gloss finish that gives a premium and luxurious look to the product. The shiny appearance, combined with other design elements, creates an attractive and engaging visual experience for the viewer.

- Intriguing Texture: Spot UV coating creates special effects that enhance the depth and dimension of flat images. The raised and glossy areas add texture, making the product visually captivating and memorable.

- Readability: Texts with spot UV coating are more legible and clear. The combination of a well-executed design and the glossy finish of spot UV makes the printed words stand out and easy to read.

- Vibrant Colors: Spot UV coating enhances the colors of the printed materials, making them appear brighter and sharper. The vibrant colors add life and visual impact to the product.

- Protective Properties: Spot UV coating provides a protective layer to the printed materials, safeguarding them from wear and tear. It helps prevent smudges, fingerprints, and reduces damage caused by sunlight and moisture.

- Durability: In addition to protection, spot UV coating also contributes to the durability of the printed materials. It helps extend the shelf life of the product by keeping out dirt and moisture. Spot UV coating can also reduce damage from exposure to sunlight and water.

- Versatility: Spot UV coating can be applied to a wide variety of materials, including paper, plastic, and metal. It offers versatility in terms of design options and can be combined with other digital embellishments or printing effects to create unique and striking visual effects.

Other Digital Embellishments

While spot UV coating is a popular choice, it can be further enhanced by combining it with other digital embellishments. Some options include:

- Soft-touch or matte coating: Adding these coatings before applying spot UV can create contrast and make the glossy areas stand out even more.

- Die-cutting: Combining spot UV with die-cutting techniques can create unique shapes and designs that catch the viewer’s attention.

- Embossing or debossing: The combination of spot UV and embossing or debossing can add depth and texture to the printed materials, creating a tactile experience.

- Foil stamping: Spot UV coating can be combined with foil stamping to create a luxurious and eye-catching effect.

Add Spot UV to Your Materials

If you are interested in incorporating spot UV printing into your projects, Duplo International can assist you. With our advanced printing and UV coating technology, we can deliver superior results at large volumes while maintaining the integrity of your products. Contact us for more information and to discuss your specific requirements.

Final Thoughts

Spot UV coating is a powerful printing technique that can elevate the visual appeal of your printed materials. By adding a glossy finish to specific areas, you can create a striking and sophisticated look that captures the viewer’s attention.

Spot UV offers numerous benefits, including enhanced shine, texture, readability, and color vibrancy. It also provides protection and durability to your printed materials. When combined with other digital embellishments, spot UV can create unique and memorable designs. Consider incorporating spot UV coating in your next printing project to make a lasting impression.

FAQs

- Can spot UV be applied to any type of material? Spot UV can be applied to a wide variety of materials, including paper, plastic, and metal. However, it is not recommended for very thin stock or packaging.

- Is spot UV coating durable? Yes, spot UV coating provides durability to your printed materials. It helps protect them from wear and tear, smudges, fingerprints, and reduces damage from sunlight and water.

- Can spot UV coating be combined with other printing effects? Absolutely! Spot UV coating can be integrated with other digital embellishments, such as soft-touch or matte coating, die-cutting, embossing, or foil stamping. Combining these effects can create contrasting elements and enhance the overall design impact.

- Does spot UV coating make colors more vibrant? Yes, spot UV coating can make colors appear brighter and sharper. The glossy finish of the coating enhances the vibrancy of the colors, making the product look more lively and inviting.

- Is spot UV coating cost-effective? While spot UV coating may add some expense to the printing process, it provides added value to your printed materials. The enhanced visual appeal, durability, and protection offered by spot UV make ita cost-effective investment in the long run. Your products will last longer and attract more attention from customers, which can lead to increased sales and brand recognition.